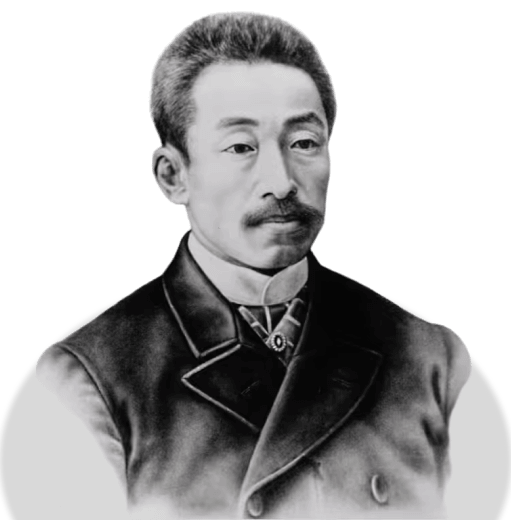

sapporo

Discover the remarkable, where world connect

We at Sapporo Beer believe that alcohol exists to enrich the lives of our customers and produce more pleasurable moments. This is Sapporo Beer’s ongoing mission.

Since the founding of the original Kaitakushi Beer Brewery, Sapporo Beer has remained unflagging in its commitment and enthusiasm for traditional craftsmanship

Through all of our initiatives, we continue to evolve in new ways and provide value that enriches the lives of our customers.

The sophisticated combination of Malt, Hop, and Water results in the smoothness of Sapporo Premium Beer.

Sapporo Premium Beers is crafted from selected ingredients, yeast, and brewed under an advanced process. Therefore, Sapporo Premium Beers asserts the position in Vietnam and global market.

Barley grains are very rich in nutrients. These grains are so many different sizes, so should be screened to ensure the more evenly the germination stage will occur.

During germination, a lot of variations happen within the barley grains. First, the nutritional components such as starch and proteins are resolved. By affecting in the direction of promoting or limiting this process of changes, brewers produce qualified malt suitable for the kind of beer they wish.

The Malt contains many enzymes which are the extremely important factors in the next stage. In the drying stage, the germination process is halted, and low-temperature air flow is used so as not to disturb the operation of enzymes. Then the Malt is dried with the hot air to control the proliferation of bacteria, preserving Malt in good condition for a long time.

Malt roots are the cause of undesirable mixed tastes. Therefore, they are quickly removed by a specialized device after the drying step.

Then, the finished malt is mashed in a silo for about one month. Prior to boiling, the malt grains are milled into particles, this process improves the efficiency of converting the starch in the grains into sugars (saccharification). However, if the particles are too small, the filtering process later will take longer

To resolve and break the crystalised structure of starch, malt is put into the boiling tank and brought into boiling water to convert into a melted form. This stage is called “gelatinization”. Enzymes will turn gelatinized starch of malt into sugars. Proteins will be resolved into peptide (amino acids chain), which plays a crucial role in creating beer foam and amino acids are the nutrients of yeast, contributing to the reproduction of yeast and to the beer flavor.

At the end of saccharification, filtering is performed to remove solids. It is the most time_x0002_consuming stage so that grains are to be ground into a moderate size, while stirring should not be overdone in the saccharification stage, which prevents the multi-sugars from being resolved.

The filtered maltliquid is transferred to the boiling tank and hops are added during the boil.

Bitterness is born during the boiling stage. Hops are known as an agent to create bitterness, but they are not the only component. A certain acid in the hops is changed during the boil and creates this bitterness. Measuring the bitterness of beer is calculated by measuring Isohumulone substance

formed in the boiling stage.

The way of adding hops during the boil can also result in the change of the beer aroma. Hops may be entirely added at the start of the boil or bit by bit gradually. To make the strong aroma of hops, a proportion of the hops is held back and only added prior to the completion of boiling stage.

At the end of boiling, the solids in the malt liquid have to be separated out. This task is performed in a vessel called "whirlpool". Malt is poured into this tank, as it spins the centrifugal force collects the denser solids into the center of the whirlpool

After undergoing the boiling stage, malt is cooled down to the fermentation temperature (8-10°C for bottom-fermenting and 15-20°C for top-fermenting), and then is provided with the necessary enzymes for the growth of yeast. Next step, yeast is put into the solution. Under the impact of enzyme fermentation, sugar transforms into alcohol (ethanol) and CO2. The young beer is formed

a week later

Young beer will be transferred to the maturing tank due to prepare for the second fermentation.The best ratio of top-fermented yeast and bottom-fermented yeast is 1:2. The beer that transferred to the storage tank will be refermented. It is when the yeast at the bottom will develop further.

Frozen under 0°C, it will be matured for several weeks. Young beer must have fermentable extracts and remain a proper amount of yeast to ensure the next fermenting stage works efficiently.

In order to completely filter yeast and other dregs in the maturing process, nets with very small holes will be used in this stage. After filtering and heating for sterilization, beer will be packaged for dispatch. Bottles and cans also undergo rigorous tests before being filled.

Empty bottles go through the bottle washer and sterilizer. During rinsing, Bottles with cracks or scratches are removed from the filling line.

Empty cans are delivered to the brewery in the airtight wraps after being inspected thoroughly by manufacturers. In the brewery, automatic equipment checks the inside of each can and a high pressure water stream will be used to rinse. Once cans are done with the washing process, they are filled with beer.

The canning process is carried out by replacing the air inside a can with Carbon Dioxide (CO2) at suitable pressure. The creation of CO2 gas pressure helps to avoid bubbles and to eliminate the oxygen which is the cause of oxidation and beer quality reduction.

Beer can can not be packed into carton boxes right after filling because they are at a very low temperature. Therefore, they must go through the warm water to reach the room temperature before settling in carton boxes.

Built in Viet Hoa-Duc Hoa Industrial Park, Duc Hoa District, Long An Province, Sapporo Vietnam Brewery is proud to be one of the most advanced technology equipped brewery

The outstanding flavor of Sapporo Premium Beer is meticulously made from the blend of the finest ingredients, highly-selected yeast, advanced production skills, and one-of-its-kind technologies along with the stringent quality control system standards from Japan in every step of the brewing process.

6,5

hectares

140+

years

40 million

liter/year